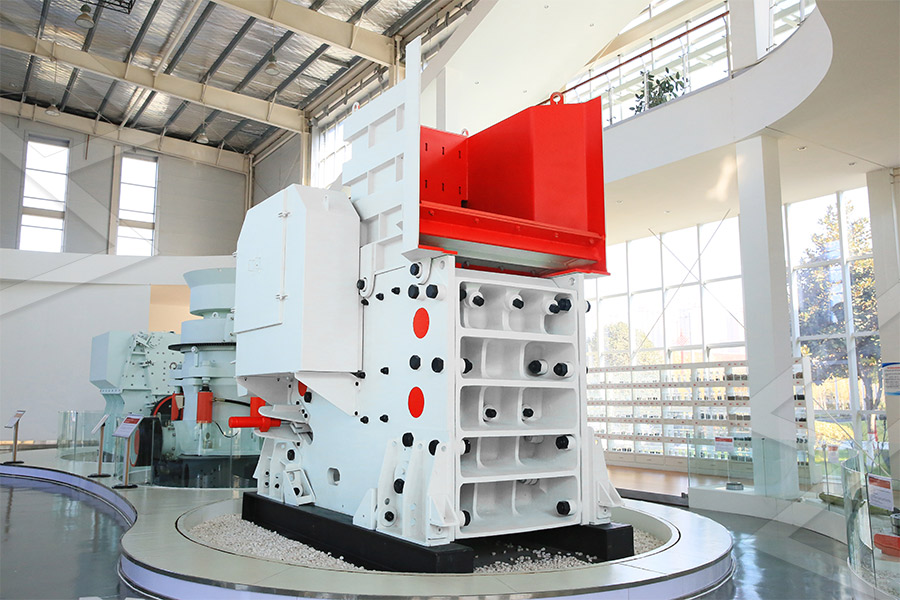

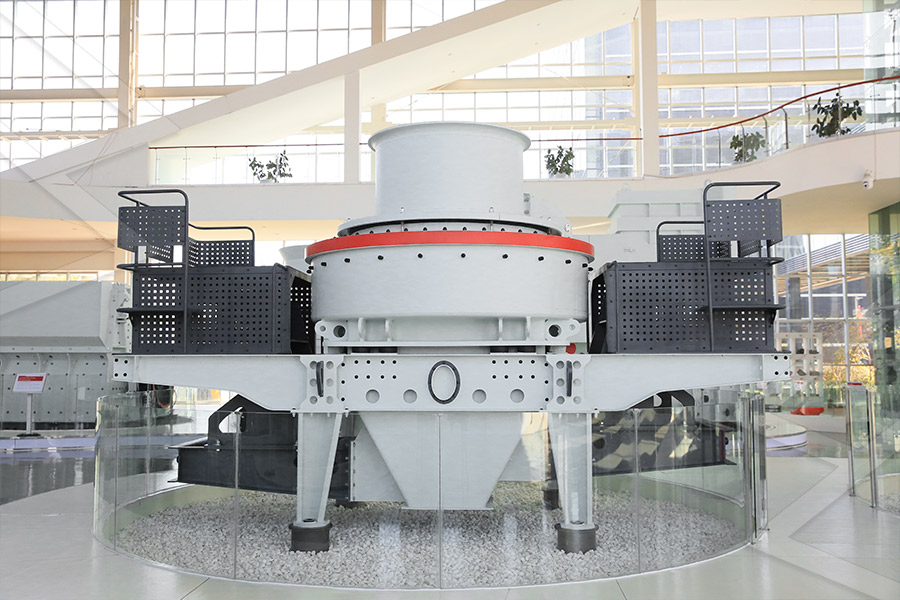

The Vertical Shaft Impact Crusher Image

.jpg)

Vertical shaft impact crusher Download Scientific Diagram

In this paper, the role of crushing operation on the cubical controlling features of coarse aggregates, and its influence on the shape distribution characteristics of aggregates (ieImpact phenomena have proven to be highly effective in the process of intense cracking and chipping, which leads to the desired separation of tThe vertical shaft impact crusher (1) Feeder; (2) splitter; (3) rotor;Cover: An image depicting the simulation of filling of a rotor inside a VSI with regards to time Created using EDEM Software Vertical Shaft Impact crushers have been used for a long time Modeling and Optimization of a Vertical Shaft Impactor forImpact phenomena have proven to be highly effective in the process of intense cracking and chipping, which leads to the desired separation of the crushed particles into smaller ones However,The vertical shaft impact crusher (1) Feeder; (2) splitter; The Standard of Excellence in VSI Crushers • Developed Replacement Wear Parts for Spokane Crushers • Repaired and Developed Components for Spokane Crushers • Developed Lid Vertical Shaft Impact (VSI) CrushersVertical Shaft Impact Crusher (MVIG) Series is specifically designed for shaping the material after a cone crusher Rock on rock designation means a few and inexpensive wear parts compared to other alternatives Adjustable speed and Vertical Shaft Impact Crushers – G Model– MEKA

.jpg)

VSI Crusher Vertical Shaft Impactor 911Metallurgist

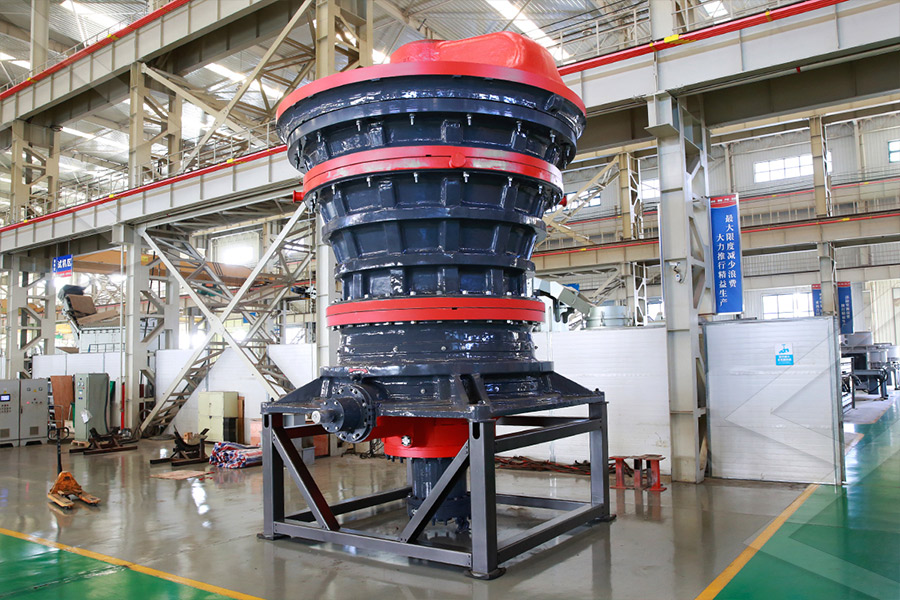

2019年3月6日 Vertical shaft impact crushers produce a small reduction ratio and arc often used for crushing tines In hammer mills the impact of a fastmoving hammer on a slowmoving rock causes shattering It can also be caused by 2023年8月7日 With high speed rotating impellers, the MIV800 Vertical Shaft Impactor throws material out from center to circumference, by using the material’s own centrifugal force to cause impact with the impeller shoes or the anvil MIV800 Vertical Shaft Impact Crusher Minyu Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quarternary stage crushing The crushers are suitable for a wide range of applications including the VERTICAL SHAFT IMPACT CRUSHERSIn this thesis, the use of vertical shaft impact crushers to crush aggregate rock to rounder particles is investigated The main aim of this is to develop and further the understanding of the Modeling of Vertical Shaft Impact CrushersVertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing These crushers are suitable for a wide range of applications including the production of high quality manufactured VSI Crushers AGGRETEK Vertical Shaft Impactors2024年1月15日 Vertical shaft impact crushers (VSI's) are usually used in tertiary crushing stations in both the aggregate and mining industries for crushing hard rock material or ores when a product material with a cubical shape and a number of fines is required [1, 2]A VSI crusher Novel design modeling for vertical shaft impactors

Vertical Shaft Impact Crushers Manufacturer in India

Highly Vertical Shaft Impact Crushers Manufacturer efficient and specifically designed for producing fine, Quality Sands and cubically shaped aggregate These crushers are the preferred choice for 3rd or 4th stage crushing Barmac® vertical shaft impact (VSI) crushers were the first vertical shaft impactors in the world The original Barmac® was developed in New Zealand over 40 years ago after which the VSI crushers have spread to thousands of crushing sites around the globeBarmac® B Series™ impact crushers MetsoLook no further than AF Minerals Equipment in Rowland Heights, CA for topoftheline vertical shaft impact crushers Rotor speed is the rate in revolutions per minute (RPM) that the rotor is spinning in the crushing chamber We calculate the rotor speed using theVertical Shaft Impact Crusher AF Minerals EquipmentVertical Shaft Impact crushers have been used for a long time to reduce the size of particles and to give particles a cubical shape profile Very few investigations have been performed on the inner workings of the VSI crusher and even fewer attempts made to Modeling and Optimization of a Vertical Shaft Impactor forCompared to compression crushers (jaws and cones), impact crushers – like the Valor Vertical Shaft Impactor (VSI) – process a wider range of material at higher tonnages and allow for more customization of rock shape and sizeValor® Vertical Shaft Impactor (VSI) Superior Industries2024年1月15日 Vertical shaft impact crushers (VSI's) are usually used in tertiary crushing stations in both the aggregate and mining industries for crushing hard rock material or ores when a product material with a cubical shape and a number of fines is required [1,2] A VSI crusher Novel design modeling for vertical shaft impactors

.jpg)

VSI Crushers REMco

For less abrasive stones and minerals, the Swing Top / Anvil Ring Vertical Shaft Impact Crusher, or ST/AR VSI, is the way to go They’re a variation of the REMco SandMax and RockMax series, but specialized These machines feature the same heavyduty design 2008年8月1日 The vertical shaft impact (VSI) crusher is a commonlyused machine in aggregate production One common application of the crusher is for the production of cubical particles in all fraction sizes VSIs produce a larger amount of fine aggregate in comparison to a cone crusher; desirable products of the aggregate producer often include those with good cubicity and a low Modelling of output and power consumption in vertical shaft impact Barmac® B9100SE is a vertical shaft impact (VSI) crusher Known for highquality cubical end products, it is generally utilized at the last crushing stage to produce aggregates, sand, material for heap leaching, or pregrinding and finished Barmac® B9100SE™ impact crusher MetsoThe Kinglink KLSeries Vertical Shaft Impact Crusher can crushed metallurgical slag, which achieve slag recycling 3 6 Model MaxFeeding Rotation Speed (r/min) Power Capacity Weight inch mm hp kW lt/h t/h lt t KL5 118 30 22582600 4060 3045 2959 30 Vertical Shaft Impact CrusherVERTICAL SHAFT IMPACT CRUSHERS (VSI) MEKA CRUSHING SCREENING AND CONCRETE BATCHING TECHNOLOGIES mekaglobal Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quarternary stage crushingVERTICAL SHAFT IMPACT CRUSHERSLearn more about Stedman's Vertical Shaft Impactor (VSI) Primers today! When it comes to producing materials such as aggregate for road making, VSI crushers use a highspeed rotor and anvils for impact crushing rather than compression force for the energy needed for size reductionWhat Is A Vertical Shaft Impactor (VSI) Primer? Stedman Machine

.jpg)

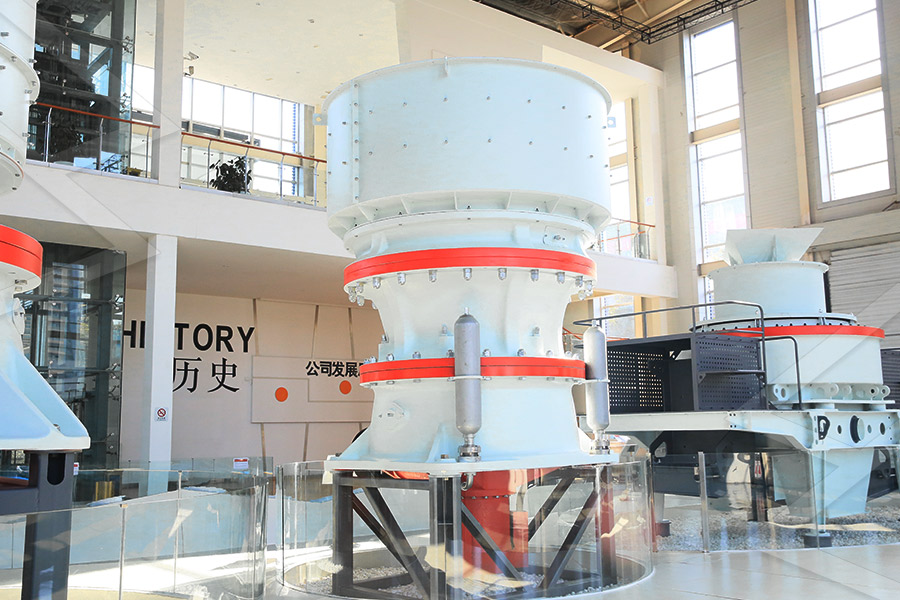

Stationary VSI crushers precision shaping SRP

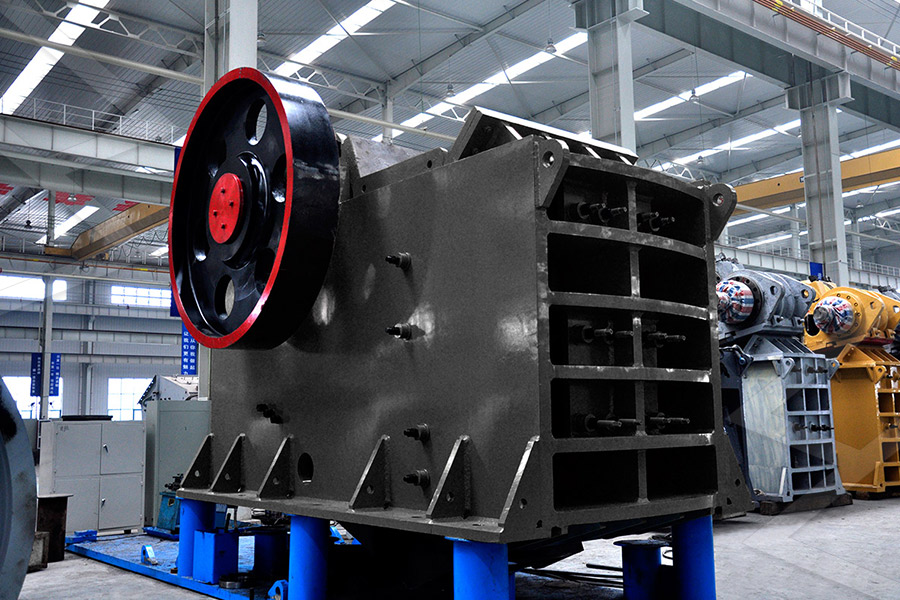

Sandvik Vertical Shaft Impact (VSI) crushers Throughout our VSI crusher range, we have put the time into what needs to be focused on and what will give you maximum performance when using them This process ensures we can design VSI crushers Vertical Shaft Impact Crusher is the most advanced impact crusher in modern world Hydraulic system used in upper cap, it is easy and convenient to maintenance and replace spare parts The feeding is our sole patent that using central feeding and central feeding with cascade feeding, the feeding method can change as per needed so as to satisfy customer's different requestVertical Shaft Impact Crusher/ VSI Crusher hybcrusher2025年1月31日 Emerson Reikdal da Cunha et al [19] applied DEM in the prediction of solids flow in a pilotscale vertical shaft impact crusher under different operating conditions A common feature of the above studies is that particle breakage was not modeled explicitly, which largely impairs the fidelity of the simulationDEM simulation of an impact crusher using the fastcutting Vertical shaft impact crusher Medium hard very hard Slightly abrasive 6:1 to 8:1 Sand and gravels 3 IMPACT CRUSHERS These crushers involve the use of impact rather than pressure to crush materials Here the material is held within a cage, with take place DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHERTypes of Impactors There are 2 main types impact crushers horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers Horizontal Shaft Impactor (HSI) The horizontal shaft impactors are the most common impactor type that can be used in recycling, primary and secondary crushing applications How does an impact crusher work? RUBBLE MASTERThe Powerscreen Trakpactor 320 is a midsized horizontal impact crusher designed for performance in quarry and recycling applications Specifications 320 tph (352 US tph) 320 tph (352 US tph) Width: 8'5" Length: 48'6" Height: 11 Impact Crusher Trakpactor 320 Powerscreen

.jpg)

What Are the Differences Between The 7 Types of

2024年7月15日 Vertical shaft impact crusher VSI crusher is generally used for the third or fourth stage crushing after the first and second crushers, which is the final link of aggregate production It is the best machine to produce Propel's Vertical Shaft Impactor, designed with insights from aggregate producers, elevates aggregate shape and enhances surface structure Discover now! SERIES UNITS AVVI 55 AVVI 75 AVVI 90 AVVI 110 AVVI 130 AVVI 160 Vertical Shaft Impactor Crusher Manufacturer PropelThe Powerscreen® XV350 vertical shaft impactor has been designed for users who require a plant that excels at producing high specification, shaped product With a range of crushing configurations available, the XV350 is versatile, productive and suitable for a number of applications including road building, concrete manufacture, manufactured sand, slag, and Impact Crusher XV350 Powerscreen%PDF16 %âãÏÓ 163 0 obj > endobj xref 163 22 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n Terex Canica VSI VERTICAL SHAFT IMPACT CRUSHERS2008年8月1日 The operating principle of the vertical shaft impact (VSI) crusher is shown in Fig 2Rock material falls down into the rotor which rotates so that the edge speed is about 50–60 m/sThe rock particles accelerate and impact the surrounding bed of rock that is formed Energy considerations in compressive and impact crushing of rockVertical Shaft Impact Crusher L Model L Series vertical shaft impact crushers use highspeed rotor or heavy duty open tables These crushers are offered in a variety of enclosed rotor or open table configurations and are convertible between three styles of crushing Crushers – MEKA

.jpg)

(PDF) INVESTIGATION OF ROCK AGGREGATE QUALITY

2021年12月3日 Previous studies presented in the literature [25,28,29,31,[39][40][41] 48, 49] mainly focused on the analysis of geometric parameters for feed material, which is unseparated material sampled VERTICAL SHAFT IMPACT CRUSHER Wide Range of Products Authorised Dealer Helpline : 1800 233 6388 nAKODA MACHINERY PVT LTD Corporate office : 139, 1st Floor, Patil Plaza, Mitra Mandal Chowk, Pune (Maharashtra, INDIA) sales@ +91 20 vertical shaft impact crusher2019年2月9日 * Crusher performance may vary depending on the feed gradation, feed moisture content, crushability of the material, crusher rpm, installed power and the crushing circuit design Please consult MEKA for specific applicationsVERTICAL SHAFT IMPACT CRUSHERS2024年2月7日 Particles in the vertical shaft impact crusher absorb and dissipate collision energy in the impact breakage The distribution of the collision energy determines the breakage rate of materials and breakage energy consumption of the entire system In this paper, the gas–solid coupling method is used to explore the regional distribution of collision energy, collision Collision Energy Analysis within the Vertical Shaft Impact Crusher Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing These crushers are suitable for a wide range of applications including the production of high quality manufactured VSI Crushers AGGRETEK Vertical Shaft Impactors2024年1月15日 Vertical shaft impact crushers (VSI's) are usually used in tertiary crushing stations in both the aggregate and mining industries for crushing hard rock material or ores when a product material with a cubical shape and a number of fines is required [1, 2]A VSI crusher Novel design modeling for vertical shaft impactors

.jpg)

Vertical Shaft Impact Crushers Manufacturer in India

Highly Vertical Shaft Impact Crushers Manufacturer efficient and specifically designed for producing fine, Quality Sands and cubically shaped aggregate These crushers are the preferred choice for 3rd or 4th stage crushing Barmac® vertical shaft impact (VSI) crushers were the first vertical shaft impactors in the world The original Barmac® was developed in New Zealand over 40 years ago after which the VSI crushers have spread to thousands of crushing sites around the globeBarmac® B Series™ impact crushers MetsoLook no further than AF Minerals Equipment in Rowland Heights, CA for topoftheline vertical shaft impact crushers Rotor speed is the rate in revolutions per minute (RPM) that the rotor is spinning in the crushing chamber We calculate the rotor speed using theVertical Shaft Impact Crusher AF Minerals EquipmentVertical Shaft Impact crushers have been used for a long time to reduce the size of particles and to give particles a cubical shape profile Very few investigations have been performed on the inner workings of the VSI crusher and even fewer attempts made to Modeling and Optimization of a Vertical Shaft Impactor for